We market, co-design, and manufacture customized solutions, with stand-alone, kit, or assembled products.

We offer a comprehensive service that begins with technical consulting aimed at analyzing the customer’s specific production and design needs. Kit design involves creating sets of technical components, selected and assembled according to the customer’s specific needs. Each kit is designed to be ready for use, facilitating assembly, installation, or maintenance.

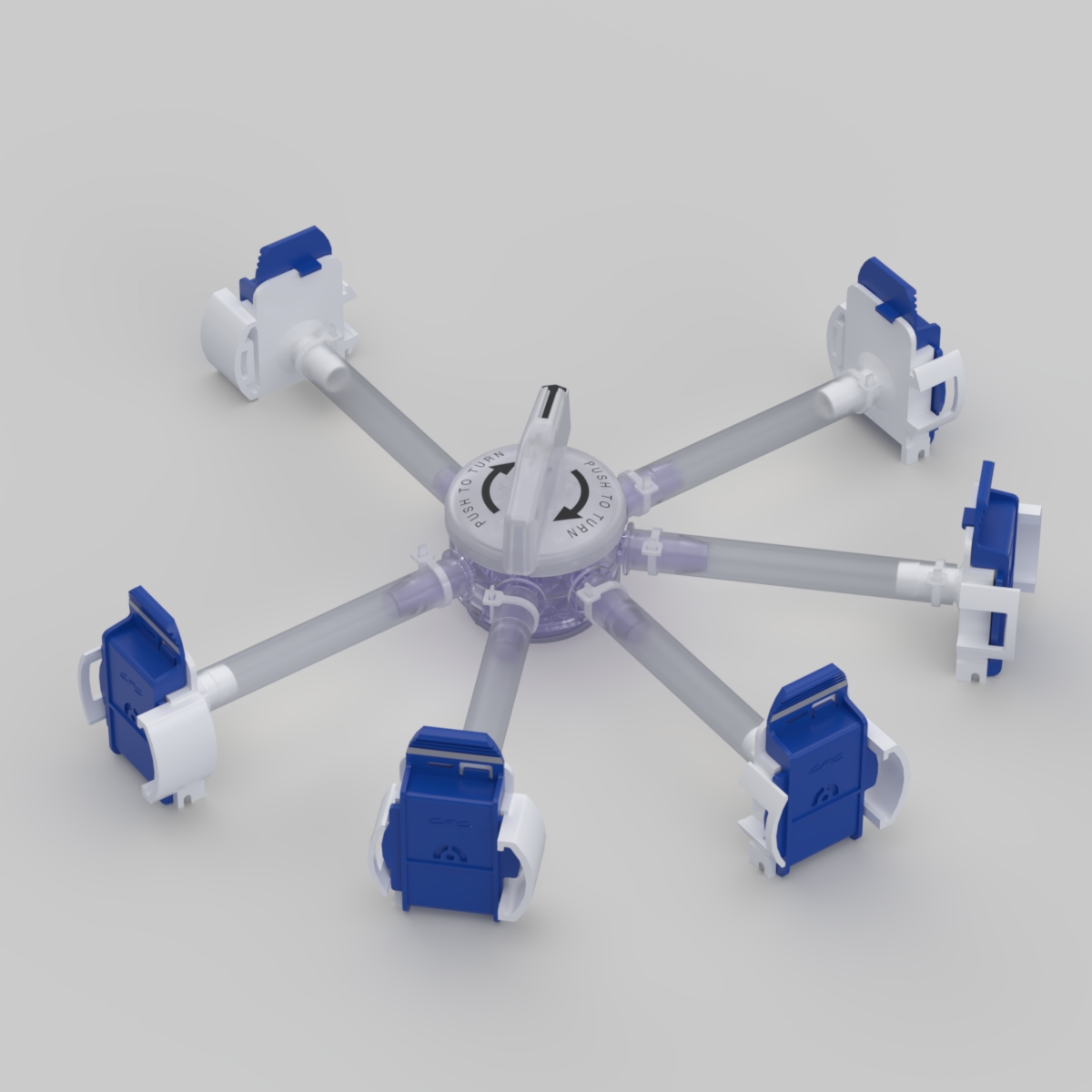

For support, we develop detailed 3D drawings to facilitate understanding the proposal and its integration into the final application. Upon request, we also manufacture individual custom components.

The advantages of the Promatec kit design service

Logistics optimization

each kit is packaged with everything needed, reducing errors and downtime.

Customization

kits are designed according to the customer's technical specifications, even for large-scale production.

Reduction of operating costs

less waste, fewer unnecessary purchases, greater efficiency.

Traceability and technical documentation

each kit can be accompanied by technical data sheets and customized instructions.

Request information about the services

We will respond within 48 hours!

Our Projects

Our kit design service is designed to meet the needs of highly specialized sectors, where component reliability, precision, and efficiency are critical. In the liquid cooling sector for high-performance PCs and data centers, customized kits enable optimized heat flow management, ensuring consistent performance and reducing the risks associated with system overheating.

Read more

The biopharma sector also relies on Promatec kits for assembling devices and systems that require precision, traceability, and compliance with the most stringent regulations. In the energy sector, and particularly in the emerging EV Charger sector, kits facilitate the installation and maintenance of electric charging stations, ensuring operational speed and component consistency. Agricultural machinery and oil & gas equipment benefit from robust, customized solutions designed to operate in extreme conditions and minimize downtime. The same applies to earthmoving machinery, where reliability, rapid response, and material resistance are essential requirements to ensure operational continuity and safety in the field.